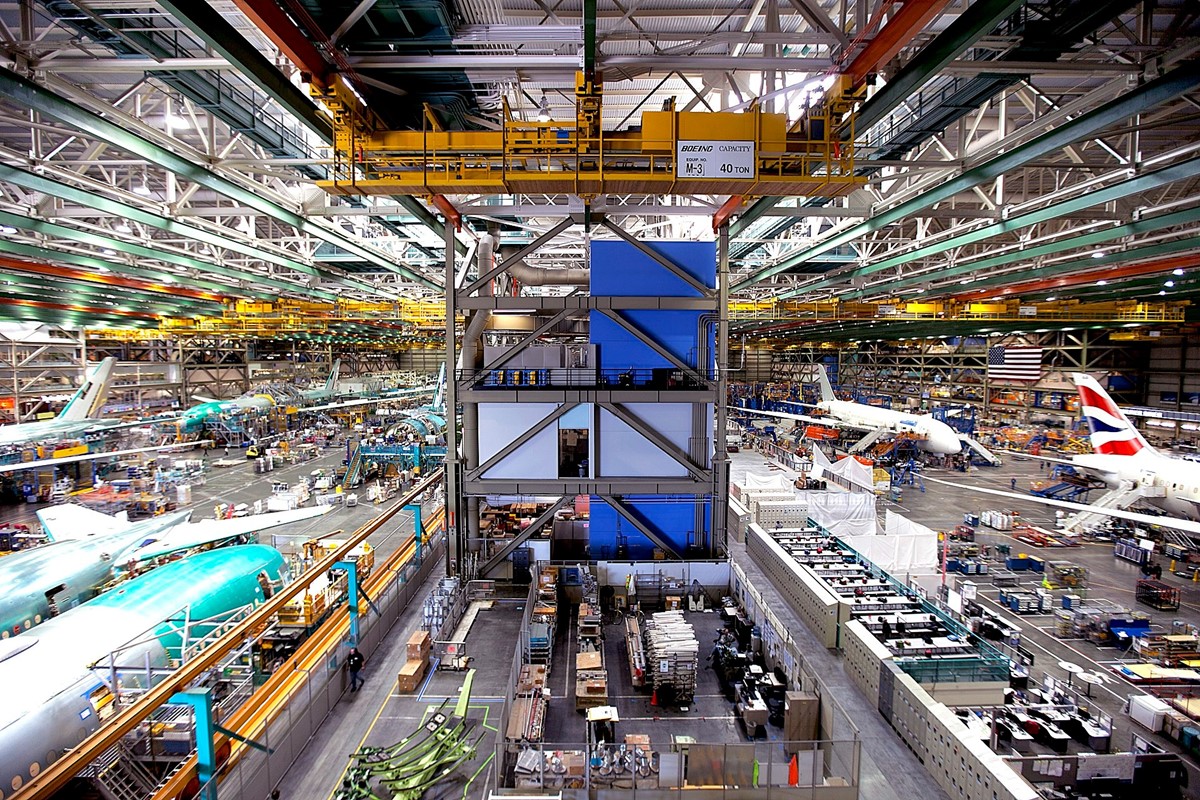

The highest standards of accuracy, reliability and performance have always been the requirements of the aerospace sector for its components. From structural connectors and fuel systems to jet engines and landing gear, each component must withstand high pressure, high temperature and continuous mechanical stress. In this harsh environment, the traditional production technology often appears to be inadequate. Investment casting is a powerful technology that has transformed the production of aircraft parts by providing unparalleled strength, precision and versatility.

As a major manufacturer of precision metal components, Ningbo Shengfa Hardware has adopted investment casting technology to meet the stringent requirements in the aerospace field. By combining decades of experience with state-of-the-art equipment, the business provides aviation customers with components that not only meet but often exceed industry requirements.

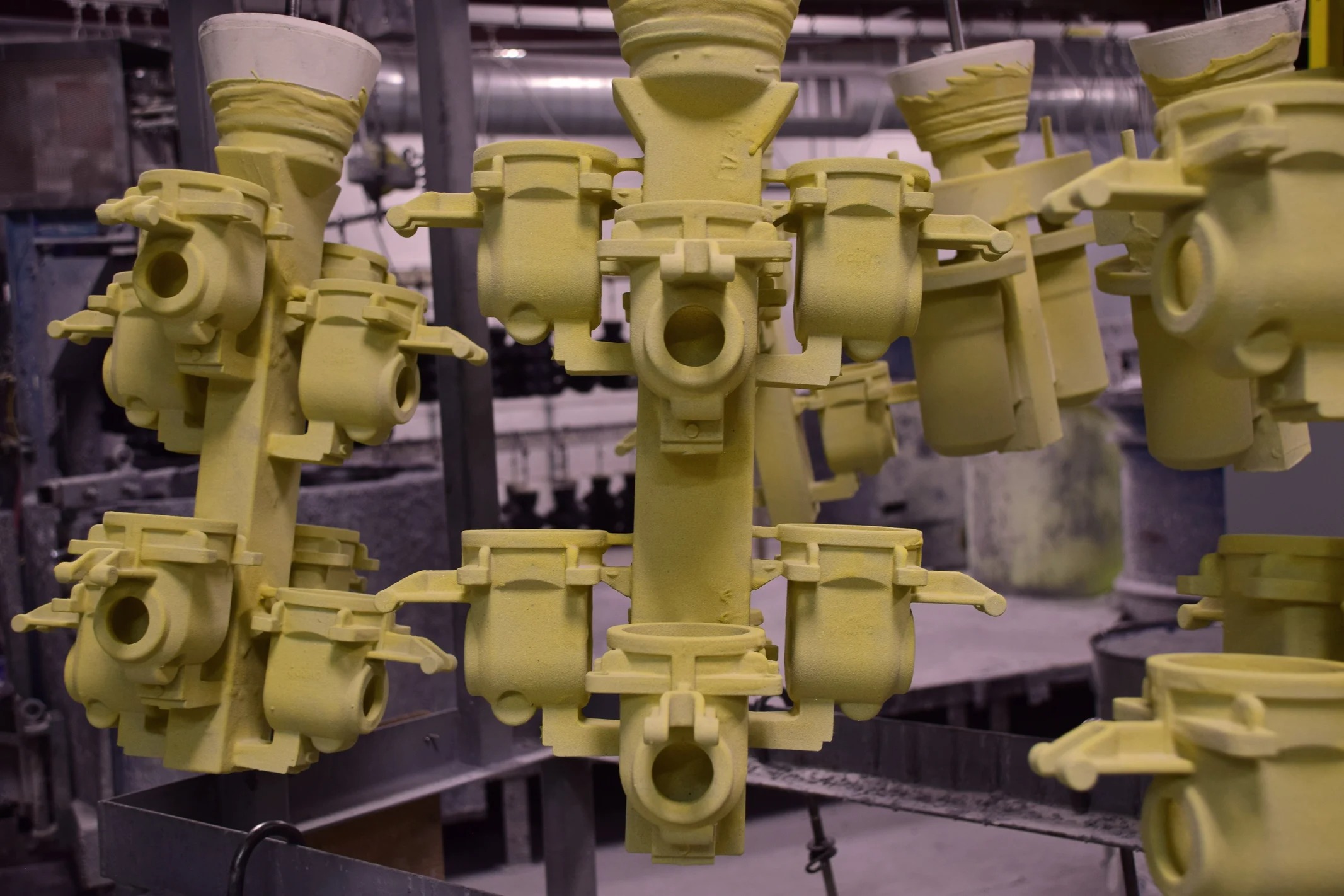

Investment casting, commonly known as lost wax casting, is a method of manufacturing molds by coating ceramic materials on wax molds. Once solidified, the molten wax is extracted from the ceramic to form a pore that can fill the molten metal. Using this technology, highly complex geometries that cannot or are difficult to achieve with conventional machining or forging can be produced.

This accuracy is essential in aerospace. Landing gear components, fuel nozzles, turbine blades, structural supports and other components must maintain accurate size in order to ensure safe and effective operation. Performance, fuel economy and structural integrity are affected by even small variances.

Investment casting has been used by Ningbo Shengfa Hardware Co., Ltd.to manufacture parts with precise tolerances and polished surfaces. The parts with accurate matching, reliable performance and low post-processing requirements are the final products.

Commercial aircraft, defense aircraft, satellites and space exploration aircraft are only a small part of many aircrafts and systems that belong to the aerospace business. Almost every category has seen the use of investment casting:

Impeller and turbine blades: Jet engines rely on precision blades that can withstand high temperatures and rotating forces. Investment casting makes it possible to optimize aerodynamics and complex cooling channels.

Fuel System Components: Investment casting provides smooth surfaces and tight tolerances for nozzles, injectors and housings to ensure efficient fuel delivery and combustion.

Landing gear and structural components: Careful material selection and precise casting are necessary to achieve the significant strength and fatigue resistance required for key supports, couplings and struts.

Space exploration equipment: Strong and light materials must be combined in satellite and spacecraft components. Complex shapes can be obtained by investment casting without sacrificing structural integrity.

In a business where failure is not an option, technical assurance components are consistent, reliable, and persistent in these applications.

Some advantages of investment casting are particularly beneficial for aerospace applications.

High precision and complex geometry: This method can create complex patterns with less machining, thereby reducing the production cycle and labor costs.

Material Flexibility: Engineers can choose the best material for each application, as investment casting can work with a variety of metals, such as superalloys, aluminum alloys and stainless steels.

Consistent quality: Through automated casting technology and strict quality control, it is ensured that each part can meet the specification requirements, thereby reducing variability and improving performance.

Reducing waste: Investment casting reduces material waste by manufacturing near-net-shape parts, which is important when working with expensive aerospace-grade metals.

Lightweight design: by reducing the weight of components, creating a complex hollow structure, improve fuel economy and cargo capacity.

By applying these advantages to its aerospace product portfolio, Ningbo Shengfa Hardware produces parts that meet strict industry certification and customer specifications.

Investment casting has been proven to be beneficial in practical aerospace projects. The precision-cast turbine blades enable the jet engine to operate more efficiently, use less fuel and produce less emissions. Investment casting improves the fatigue resistance of landing gear and structural parts, reduces maintenance requirements, and improves operational safety.

In addition, the application of advanced materials such as titanium and superalloys in the aerospace field makes investment casting more important. Processing these materials is usually challenging, costly and time-consuming. However, investment casting significantly simplifies production by directly producing complex morphologies in the metal.

Ningbo Shengfa Hardware has successfully delivered a range of aircraft components that meet stringent certification standards and support major international aerospace projects using these advanced materials.

In aircraft manufacturing, quality cannot be compromised. Investment casting from the creation of wax mold to the formation of ceramic shell, metal casting, finishing, every link needs to be carefully considered. In order to ensure the normal operation of each component, Ningbo Shengfa Hardware has a strict quality management system, including material testing, surface analysis, size detection, etc.

Through the integration of cutting-edge technology and expert technology, Ningbo Shengfa Hardware ensures that the parts obtained by aerospace customers are not only accurate, but also strong enough to withstand harsh operating conditions.

In addition, investment casting encourages creativity in aircraft design. Engineers can now experiment with lighter, more efficient, pneumatic designs without the constraints of conventional production. Better structure, internal cooling channels and hollow components are helpful to improve performance and reduce operating costs.

The experience of Ningbo Shengfa Hardware gives aerospace designers a trusted partner who can transform ideas into functional components. To verify that parts meet performance and regulatory standards, their team works directly with customers to improve casting processes, select materials and adjust designs.

Only with the development of aircraft technology will the demand for durable, lightweight and high-performance components increase. Investment casting has a special position in meeting these needs because it provides efficiency, accuracy and flexibility that traditional production technologies cannot match.

Ningbo Shengfa Hardware is committed to maintaining a leading position in the field of investment casting technology by continuously investing in cutting-edge machinery, knowledge-based employees, and research to help the aerospace industry. Their casting parts are critical to expanding the capabilities of contemporary aircraft systems, from space exploration to commercial flight.

Investment casting has changed aerospace production and provided a reliable way to manufacture complex and high-performance parts. It has become an important area for every little detail, because it has the advantages from increasing strength and precision to reducing waste and material adaptability.

For engineers and aerospace manufacturers pursuing quality, reliability and innovation, Ningbo Shengfa Hardware provides results-driven investment casting expertise. Components that meet the highest performance and safety standards are guaranteed by their commitment to precision, excellent materials and strict quality control.

With the continuous innovation and growth of the aerospace industry, investment casting will continue to be the cornerstone of advanced manufacturing with the support of trusted partners such as Ningbo Shengfa Hardware, so as to produce power flight components safely, efficiently and sustainably.