The high number of motor vehicles has caused serious motor vehicle exhaust pollution. The nitrogen oxides and volatile organic compounds emitted by motor vehicles reached 5.95 million and 1.96 million tons, respectively, accounting for 33.3% and 19.3% of the total national emissions. Therefore, driven by the "Blue Sky Defense War" and "Dual Carbon" policies, the situation of automobile emission reduction and low-carbon development is more urgent.

The overall consumption reduction target of fuel passenger cars is constantly increasing, and new energy vehicles have significant potential to help energy conservation and emission reduction. According to the "Energy-Saving and New Energy Vehicle Technology Roadmap 2.0" officially released in October 2020, the average annual decline in fuel consumption per 100 kilometers of passenger cars in my country will gradually increase from 2020 to 2035, and the pressure to reduce emissions will increase year by year. However, according to the "China Passenger Car Enterprise Average Fuel Consumption and New Energy Vehicle Credit Calculation Table" issued by the national ministries and commissions from 2016 to 2019, it can be calculated that the actual average fuel consumption per 100 kilometers of new traditional energy passenger cars from 2016 to 2019 was 6.88L, 6.77L, 6.62L and 6.46L respectively, which is always higher than the standard fuel consumption of 6.7L, 6.4L, 6L and 5.5L. However, due to the continuous increase in sales of new energy vehicles, the overall average fuel consumption per 100 kilometers of new passenger cars is lower than the standard value, and the pull is getting bigger and bigger. It can be seen that new energy vehicles have great potential for energy conservation and emission reduction. With the gradual increase in the penetration rate of new energy vehicles, the pressure of energy conservation and emission reduction in the automotive industry can be further alleviated.Various aluminum alloy accessories produced by Ningbo Shengfa Hardware are also used in various new energy vehicles.

The technical roadmap clearly defines the development goals of new energy, and the sales of energy-saving and new energy vehicles will account for 50% each in 2035. To further promote the low-carbonization of automobiles, the Energy-saving and New Energy Vehicle Technology Roadmap (Version 2.0) proposes the vision and goals of "the total carbon emissions of the automobile industry will reach the peak ahead of the national carbon emissions commitment around 2028, and the total emissions will drop by more than 20% from the peak by 2035" and "new energy vehicles will gradually become mainstream products, and the automobile industry will achieve electrification transformation". The specific milestone goals are as follows: by 2035, the annual sales of energy-saving vehicles and new energy vehicles will each account for 50%, and the automobile industry will achieve electrification transformation; the number of hydrogen fuel cell vehicles will reach about 1 million, and commercial vehicles will achieve hydrogen power transformation.

The global electrification trend continues to accelerate, and the penetration rate of new energy vehicles continues to exceed expectations. According to data from the International Energy Agency (IEA), from 2010 to 2020, as governments around the world accelerated their electrification transformation and the automotive industry marched towards the "New Four Modernizations", global new energy vehicles achieved annual sales growth of "ten consecutive years", with a CAGR of about 81%, and the penetration rate of new energy vehicles (pure electric + plug-in hybrid) increased from 0.01% to nearly 4%. Since the beginning of 2021, China and Europe, as the world's top two new energy vehicle markets, have continued to exceed expectations in sales. In 2021, the cumulative sales of new energy vehicles in China reached 3.521 million units, up 158% year-on-year, and the penetration rate reached 14.2%, an increase of 8 pct, breaking through double digits for the first time. During the same period, the sales volume of new energy vehicles in Europe reached 2.142 million units, up 70% year-on-year, and the penetration rate reached 14.6%, an increase of 6 pct, continuing the super-high prosperity since 2020; the sales volume of new energy vehicles in the United States reached 652,000 units, up 101% year-on-year, and the penetration rate reached 4.3%, an increase of 2 pct, and it is expected to reach 8% in 2022.

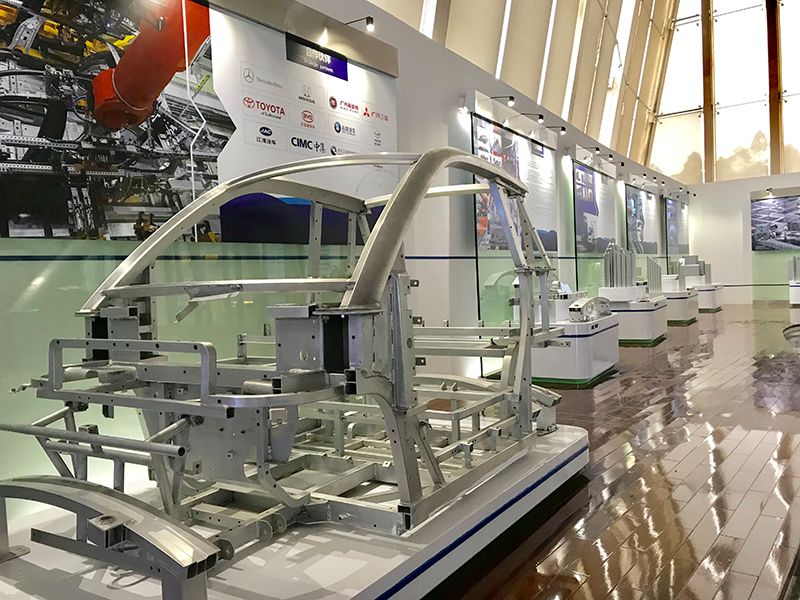

The weight of the vehicle restricts the consumption reduction and the improvement of the endurance, and the demand for lightweighting has emerged. The power system of electric vehicles includes three major systems: battery, motor and electronic control, which usually account for 30~40% of the total mass of the vehicle. At the current level of power battery energy density, the power system mass and space proportion of electric vehicles and general new energy vehicles are significantly higher than those of traditional fuel vehicles, and the vehicle weight is 5~25% higher than that of traditional fuel vehicles. In the future, after being equipped with relevant configurations of intelligent networking, the vehicle weight will further increase. Taking GAC Toyota's C-HR and its pure electric model C-HR EV as examples, the curb weight of the pure electric model is 18.27% higher than that of the fuel version. At present, due to the problems of excessive weight of the electric drive system and low maturity of supporting facilities, the actual endurance of electric vehicles is severely restricted, which has become an important factor affecting consumers' car purchase decisions. Therefore, reducing the weight of the whole vehicle to improve the endurance of the vehicle has become a hot technical route to solve this problem, and the demand for lightweight electric vehicles has emerged.

Lightweighting can comprehensively improve consumption reduction and endurance efficiency, and is one of the effective means of energy conservation and emission reduction. Under the demand for energy conservation and emission reduction and the continuous improvement of the long endurance of new energy vehicles, automobile lightweighting is currently the most direct and effective means. For every 10% reduction in the curb weight of electric vehicles and fuel vehicles, the endurance will increase by 6-8%, and the exhaust emissions and energy consumption will be reduced by 6-8%. In addition, under the premise of ensuring safety strength, the lighter the weight of the car, the shorter the acceleration time, the more flexible the dynamic response of the body, and the reduced braking distance, body vibration and noise. As consumers' requirements for car driving experience continue to improve, the improvement in economy, safety and comfort brought by lightweighting will better meet the needs of consumers, and the competitive advantage of car companies adopting lightweighting technology will become more prominent. Therefore, using lightweight solutions to improve energy saving and reduce consumption and endurance of electric vehicles has become the current priority.Ningbo Shengfa Hardware uses the latest technology and high-quality aluminum materials to provide various lightweight components for major automobile companies.