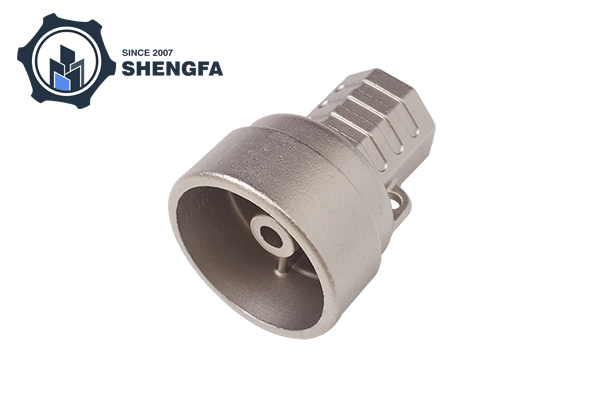

Silica Sol investment casting is a casting process that uses silicon solution as a binder to build a mold. Metal castings produced by silica sol casting have a smooth surface and high precision.

Compared with other casting methods, silica sol investment casting has many advantages over other methods. The surface of parts produced by silica sol casting is smooth, which shortens the process of post-casting finishing. In addition, the size of the mold manufactured by silica sol casting meets the requirements, which helps to reduce material waste during processing.

This method is very suitable for complex parts that require thin walls, sharp corners and fine details, because these features are challenging to meet with traditional casting methods.

Although the initial cost of silica sol casting is high compared with methods such as water glass casting, the shortened post-casting processing process and the ability to produce complex parts directly affect the low cost in the later stage.