Ningbo Shengfa Hardware, as a well-known manufacturer with many years of experience, is at the forefront of this development and provides high-quality investment casting solutions for industry applications. By adopting advanced casting technology and strict quality control, the company ensures that all parts not only meet, but also often exceed the expectations of customers. Because of its excellent material utilization, surface quality and design flexibility, investment casting is being adopted by industries around the world, including construction, automotive and aerospace.

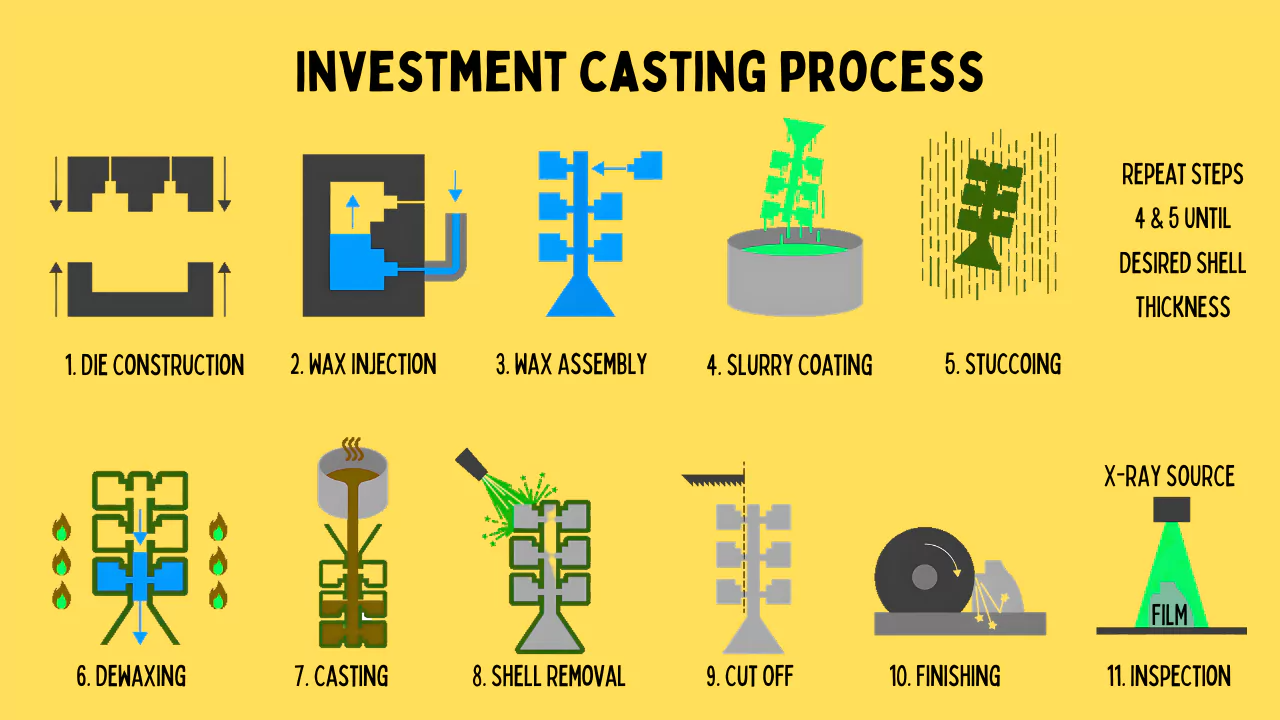

The process starts from the wax mold, and the surface of the wax mold is coated with ceramic material to form a shell mold. Once the wax melts, the molten metal is poured into the cavity to form a component that perfectly reflects the original pattern. Investment casting is known as difficult or even impossible to manufacture by traditional methods (such as machining or forging) because of its ability to produce highly detailed and dimensionally accurate parts.

The advantages of this technique are numerous:

1. Complex geometry: Investment casting enables manufacturers to produce complex shapes with small details by removing a large number of machining processes.

2. Surface finishing: The parts almost do not need further polishing, which reduces the cost and accelerates the production speed.

3. A wide range of material selection: A variety of alloys, such as aluminum, carbon steel, stainless steel, and unique heat-resistant materials, are supported by this method.

4. Dimensional accuracy: This technology is very suitable for precision-critical enterprises, because its tolerances are very strict.

5. Material efficiency: Investment casting is more economical and environmentally friendly than machining because it produces less waste.

Because of these advantages, investment casting is particularly suitable for high-performance sectors where component quality and reliability are directly related to efficiency, durability and safety.

Investment casting has many uses. Brackets, gear housings and turbocharger components are one of the elements used in the automotive field and must be both robust and lightweight. In the field of aerospace, investment casting is very important for the production of structural parts and turbine blades that can withstand high pressure and high temperature.

Investment casting also contributes to the agricultural machinery industry due to precision gears, casings, and linkages that are critical to on-site durability. At the same time, in construction equipment, castings provide the toughness required to withstand heavy loads and continuous use.

Since its establishment in Ningbo, China in 2007, Ningbo Shengfa Hardware has gradually improved its ability to cater to global customers in the fields of industry, automobile and agriculture.

The business provides customers with a comprehensive production solution under the cover by integrating investment casting with CNC machining, surface treatment, and quality inspection. This eliminates the need for multiple suppliers and ensures consistency, reduced lead times and cost optimization. This positioning positions Ningbo Shengfa Hardware as a leader in investment casting solutions as industries demand increasingly sophisticated parts.

Thanks to its cutting-edge machinery and dedicated engineers, the manufacturer offers customized casting services tailored to the customer 's requirements. Ningbo Shengfa Hardware ensures that every product meets strict performance and durability standards, whether it is manufacturing small, precision parts, or manufacturing larger, heavy parts.

The core of investment casting is quality control. Precision detection techniques such as X-ray analysis, magnetic particle testing and three-dimensional measurement are used to identify internal defects and confirm dimensional accuracy. This ensures that each part has the ability to withstand the operational difficulties that arise in the real world.

In order to improve the sustainability and effectiveness of casting, Ningbo Shengfa Hardware is unswervingly committed to continuous innovation and R&D investment. By reducing energy and material waste, the company not only produces high-quality products, but also promotes eco-friendly manufacturing practices.

The increasing importance of investment casting is reflected in the trend of global automotive and aerospace design towards lightweight and high-strength solutions. With the increasing emphasis on energy efficiency and low emissions, the demand for precision casting parts will increase. These environmental goals are directly supported by investment casting, which allows manufacturers to manufacture lighter components without sacrificing strength.

In agricultural production, the equipment must withstand harsh conditions and long running time. The investment in castings ensures the reliability of the equipment and low maintenance costs. Durable parts increase the life of machines and increase the productivity of farmers and equipment manufacturers.

Future industrial production will increasingly rely on technologies that provide sustainability and accuracy. In view of its ability to meet these needs, investment casting is expected to become the key to this development. Enterprises that can combine global supply capacity with precision casting technology will be at the forefront of the industry.

With rich experience, originality and dedication to customer satisfaction, Ningbo Shengfa Hardware can continue to become a reliable partner in this journey. This business contributes to the next stage of industrial manufacturing by maintaining capacity expansion and adapting to new market demands.