In today's fast-paced industrial environment, reliability is the foundation of everything. Whether it comes to cars, heavy machinery, urban infrastructure, or renewable energy, the accuracy and strength of each component will have an impact on the final product. Because of this, hardware - the tiny, powerful components that keep everything running - is at the core of modern engineering. Therefore, the manufacturing concept of Ningbo Shengfa Hardware is based on the unremitting pursuit of strength, accuracy and reliability.

In the field of hardware, precision is a promise, not just a technical requirement. Each washer must evenly transfer force, each bolt must be accurately matched, and each nut must bear the tension. Small changes in strength or size often lead to expensive failure.

Every step in the production process of Ningbo Shengfa Hardware Factory has been injected with accuracy. We start with careful selection of raw materials to ensure that the steel or alloy we use meets precise mechanical and chemical requirements. Then, we optimize the structural integrity and uniformity of each component by designing forging, machining and heat treatment procedures.

With every piece leaving our factory, we make sure precision isn't an aspiration — it’s the minimum standard.

Reliability is a key difference in the global hardware business. It shows that every piece of goods has fulfilled the commitments made. It refers to the goods that have always played a flawless function. In addition, it also suggests that they may depend on you for many years, not just once.

Our factory is unique in this regard. Through decades of dedication to quality and consistency, we have established a trusted leading brand reputation in hardware solutions for forged steel parts, fasteners and designs. Our customers realize that by choosing us, they are investing in hardware that performs well in any setting or application.

Reliability is another aspect of reliability. We guarantee fast delivery times and reliable delivery times, even for customized orders, thanks to the combination of digital technology, cutting-edge logistics and knowledge workers. At the end of the day, providing peace of mind is more important than simply delivering goods.

The way materials are formed, processed and finished is where power begins in the product. Because forging improves the mechanical strength, increases the structural integrity and prolongs the product life, Ningbo Shengfa Hardware specializes in the production of forged steel parts. Whether it is used in automobiles, drilling equipment, or building infrastructure, forged components have better performance under strain and longer life under stress.

In our factory, forging is a modern, technologically advanced process, rather than an outdated technique. Before forming, due to the control of the temperature system, the components are heated to the ideal temperature. Automated handling and robotic arms improve production efficiency and reduce human error. We can create very accurate molds, and reliable results can be obtained even in large quantities, thanks to computer-aided tools.

Our superb machining skills enhance our forging advantages. After each part is forged, it is threaded, drilled, machined or formed to precise specifications. Thanks to this combination of power and precision, every hair product is reliable under the most demanding conditions.

Quality is designed through control and discipline; this is not accidental. We have a comprehensive quality management system in Ningbo Shengfa Hardware to monitor every step from the final packaging to the inspection of incoming materials.

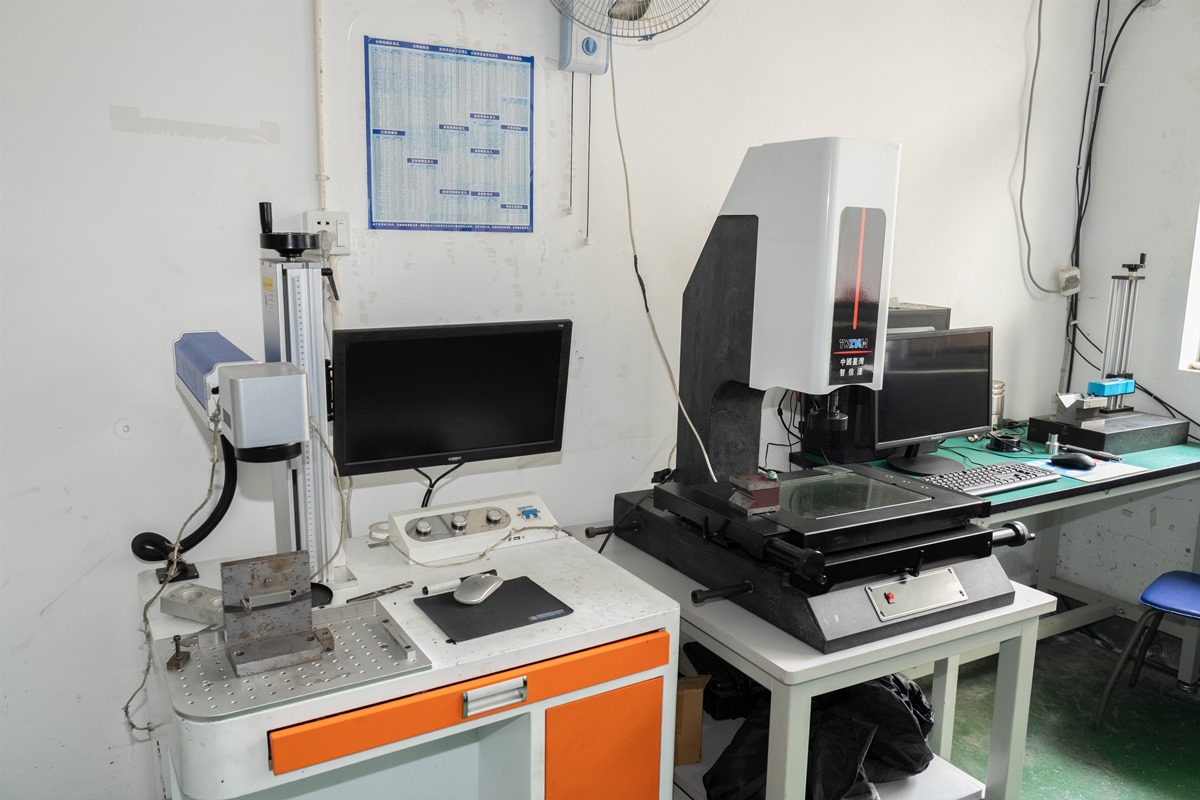

The grain orientation, chemical composition and tensile strength were tested on the original steel. Automatic measuring equipment uses micron accuracy to confirm dimensions and tolerances in the production process. After the processing is completed, the parts are subjected to thread fit verification, salt spray corrosion test and surface quality inspection. Before any purchases are shipped, our inspectors ensure that they meet the customer's specific requirements and international requirements.

Performance is not the only demand of today's enterprises. They require companies to take action in moral, social and environmental aspects. As the hardware supply chain continues to evolve globally, sustainability has become an important consideration in production decisions.

The sustainable production mode is the priority choice of Ningbo hardware. We are actively committed to reducing environmental impacts through the use of eco-friendly surface treatment technologies, energy-saving equipment and material recovery. In order to promote long-term business and ecological balance, we abide by international rules and regularly assess our impact.

By doing so, we help our customers achieve their sustainable development goals, but also increase our value as a provider.

Future-oriented innovation is critical to today's reliability. Due to the emergence of electric vehicles, smart devices and renewable infrastructure, with the transfer of global industries, customized, high-strength, lightweight parts demand more and more.

At Ningbo Shengfa Hardware Factory, our R&D team works directly with customers to create new designs, modify materials, and evaluate performance improvements. We help customers stay ahead of market changes through precision engineering, better alloy selection and mold redesign.

For us, innovation is not just about creating new things; it is also about improving existing work and predicting future development.

In every machine, bridge and building there are components that must always work. These components are the lifeblood of performance; they are not just metals. If our process is to reflect the accuracy, our process is to reflect the power, then our factory commitment to each customer is reliable.

We ensure that the smallest part has the greatest power by investing in sustainability, quality and technology. Because when the world depends on the connection, every bolt is important, and every bolt needs to be manufactured to last.