A basic idea supporting all great machines, bridges, and structures is that strength starts with the smallest component. Although bolts, nuts, washers and fasteners seem to be commonplace, they form the basis of many industries in the world. Ningbo Shengfa Hardware has become one of the most prestigious brands in the field of metal component production in China, which proves that in today 's fierce competition in precision engineering, real strength is established through commitment, quality and innovation.

The goal of our factory is to create reliable, lasting and accurate hardware products for consumers all over the world. The company was originally a small workshop serving domestic machinery manufacturing enterprises in the industrial town of Ningbo. Over time, it has developed into a cutting-edge factory for export to customers in Europe, North America and Southeast Asia due to stable investments in technology, expert processes and international standards.

It is unique not only because of its ability, but also because of its constantly improving culture. The organization realized that in today 's harsh hardware industry, perfection cannot be achieved quickly; instead, it must be developed on a bolt-by-bolt basis, process-by-process.

Precision forging is the basis of each germinal product and the key to processing raw steel into high-performance parts. Compared with casting, forging improves the tensile strength and durability of the metal by refining the grain structure. Strict quality control is carried out on each bolt and nut produced by us to ensure its dimensional accuracy, excellent surface finish and reliable pressure bearing performance.

In order to maintain the integrity of the metal, the equipment uses a precision forging production line with a temperature control system. Each component is subjected to finishing, heat treatment and post-forging inspection to ensure that it meets international standards such as ISO, DIN and ASTM. The result is a product that is ideal for use in the automotive, construction, energy and heavy machinery industries because it can withstand high levels of stress and environmental conditions.

By maintaining tight control over the entire production chain, we ensure that every piece leaving its facility carries not just weight, but trust.

Quality control is the invisible cornerstone of every hardware manufacturing success story. For germinal, quality is a way of thinking, not a department. The business adheres to the concept of zero defects, backed by skilled professionals and modern testing equipment. From the procurement of raw materials to the final packaging, every step is recorded and confirmed.

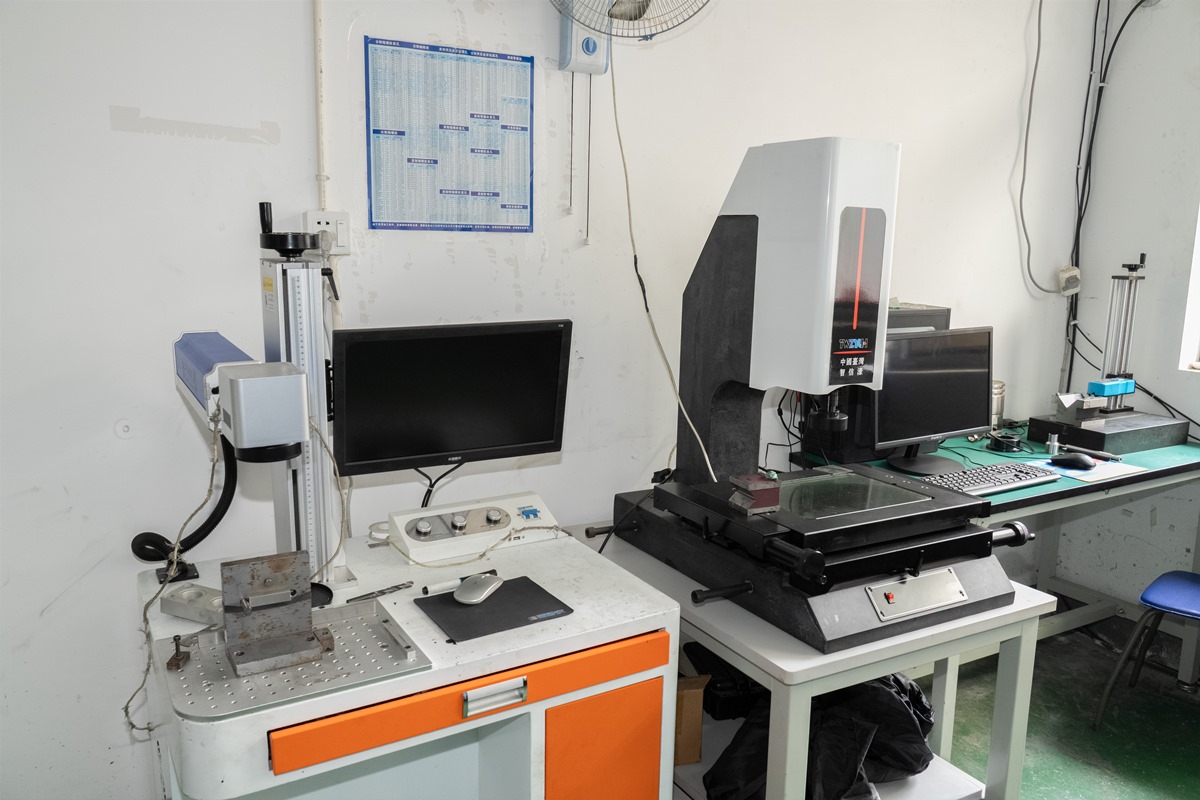

Before starting production, the composition and strength of each batch of steel were tested. With an automatic measuring device and a 3D inspection system, dimensions up to the millimeter level can be determined. Through salt spray corrosion inspection, tensile test and random sampling, it is ensured that each product meets or exceeds customer specifications.

Ningbo Shengfa Hardware has won the unanimous praise of international consumers with reliability as the primary goal because of its persistence in quality. Working with us provides many customers with less replacement, less downtime, and ensures that their supply lines are always robust.

Traditional processes are still important, but technology has changed the way industry works today. One of the best examples of how digital systems can improve manufacturing speed and accuracy is Shengfa. The company has implemented intelligent production scheduling, so that the machine can run with minimum waste and maximum efficiency.

Automation is now a major factor; CNC machining equipment ensures uniform tolerances between large quantities, while the manipulator manages repetitive tasks. These advances reduce lead time while improving product homogeneity.

In addition, thanks to data-driven management, we can track every order from surface treatment and packaging to forging and threading in real time. Customers can instantly update their production status, enhancing openness and confidence.

With the transformation of the world towards sustainable industry, our factory has taken major measures to reduce its impact on the environment. The factory uses environmentally friendly coating and cleaning technology to recycle excess materials and use energy-saving machinery.

Closed-loop cooling systems and water-based treatment reduce resource use and pollution. We have contributed to a more environmentally friendly industrial ecosystem without sacrificing performance by striking a balance between productivity and responsibility.

In addition, the strategy meets the needs of global customers for ethical and environmentally responsible procurement. Sheng 's efforts show that industrial excellence and environmental responsibility can coexist in an era where sustainability determines brand reputation.

Reliability, or the ability to meet commitments on time, is the foundation of any successful collaboration. Our factory has established a lasting relationship with industrial equipment manufacturers, OEM customers and international distributors. Whether it is manufacturing ordinary bolts or specially developed fasteners, the company has flexibility, fast production cycle and timely communication.

Its exports have been sold to Germany, the United States, Japan and other countries. Through the understanding of a variety of international standards, we ensure the smooth integration of its hardware parts into the foreign supply chain.

Consumers often praise the company's product quality and service concept, which reflects its goal of providing comprehensive solutions, not just parts.

A winning bolt is not just a piece of steel; it is the product of decades of craftsmanship, creativity and attention to detail. According to the organization 's point of view, real strength is characterized by trustworthiness, skill, and trust, not just quantified by Newton or stretching limits.

Every element, from the precision of the thread to the gloss of the surface, conveys the story of a maker committed to quality. The excellence of our factory ensures that its products continue to be the industrial basis for creating the world.

With the development of the global hardware market, there is an increasing demand for more powerful, faster and smarter solutions. It will be dominated by factories that strike a balance between production and precision, as well as between tradition and technology.

That future is reflected in Ningbo Shengfa hardware. The company has built a reputation far beyond China 's borders because of its unwavering commitment to quality, speed and sustainability. In addition to the robustness of the structure, every bolt it manufactures reflects the spirit of a company's emphasis on doing things - every time, every detail, every bolt.

Ningbo Shengfa Hardware ensures that every link is solid in a society where relationships are essential.