From heavy machinery and energy to construction and automobiles, every global business is based on many parts that few people see. The hidden frame of modern engineering is composed of bolts, nuts, washers, brackets, forgings, etc. Under these basic elements, it is an industry that has undergone major changes in the past 20 years. Ningbo Shengfa Hardwareis one of the most dynamic examples of this transformation, from a small workshop to a smooth, internationally renowned hardware manufacturer.

Like many successful cases of China's manufacturing industry, Ningbo Shengfa Hardware was originally just a small workshop, with a straightforward goal: to provide reliable and high-quality metal parts for local machinery manufacturing enterprises. In the early days, the productivity was limited, the production was done manually, and the equipment was simple. Nevertheless, the enterprise still adheres to its basic creed: process is the basis of reliability.

Consumers appreciate this dedication, and demand is increasing rapidly. The workshop grew, investing in better equipment, greater space, and more qualified personnel to handle ever-increasing orders. In the forging and machining of hardware products, from a small supplier quickly grew into a prestigious regional brand.

Our factory's embrace of modernization has brought about a real change. Traditional production technology is not enough, because global companies need better coatings, stricter tolerances and faster delivery cycles.

In this regard, Ningbo Shengfa Hardware has taken decisive action. Our has invested heavily in digital production management systems, high-precision CNC machining equipment, automated forging production lines, and precision testing equipment. This change is both cultural and technical. Each team member gains an understanding of the importance, efficiency, and consistency of data in their daily operations.

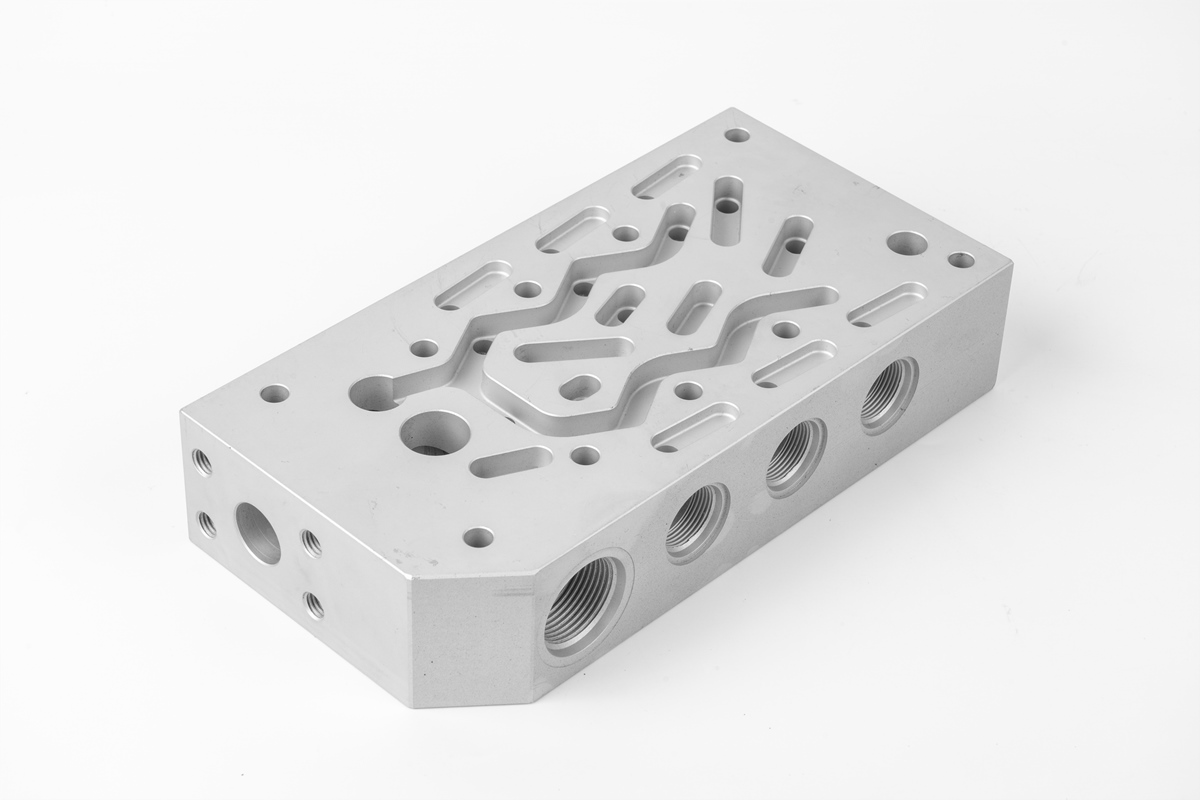

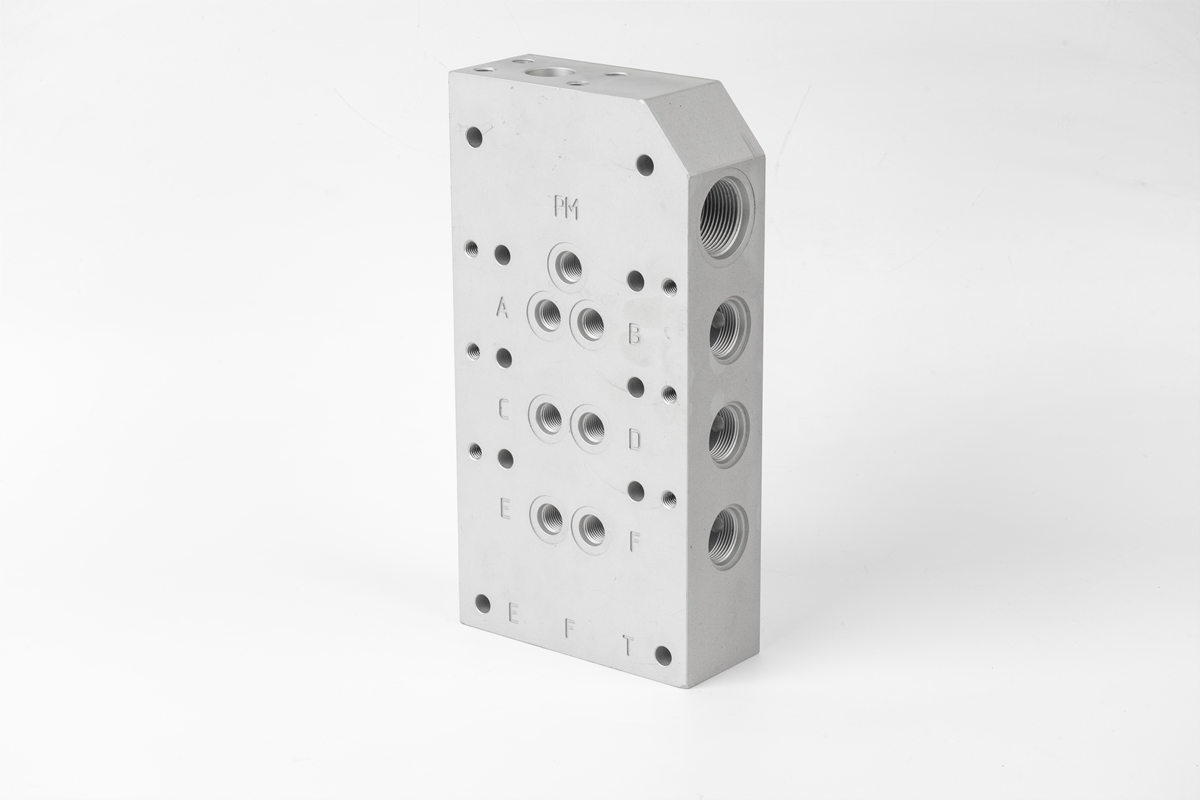

The final product is a factory setting that can produce large quantities of goods with significant precision. Formally, the workshop has been transformed into an advanced hardware manufacturing industry to cater to the international market.

The fully integrated production process is one of our biggest advantages. The plant manages forging, machining, heat treatment and surface finishing internally, rather than shrinking key processes like small workshops. There are three main advantages of this vertical integration:

Stable quality: By monitoring each stage under uniform standards, consistent mechanical properties and dimensions are ensured.

Fast Delivery: Shorten production cycles and ensure on-time delivery with less reliance on external suppliers.

Cost reduction: Thanks to effective resource management and internal scheduling, customers can obtain low pricing without compromising performance.

One of the key elements of transforming the business from a workshop-level enterprise to a top-level hardware manufacturer is this unified production chain.

The identity of germinal always revolves around forging. By enhancing the grain structure and tensile strength of the metal, forging produces parts that can withstand high pressure and make them very suitable for industrial, automotive and structural use.

Our factory uses a precision heating system, automatic hammering equipment and precisely controlled molds to ensure that each forging meets strict material and size requirements.

Thanks to this combination of contemporary machinery and traditional metalworking expertise, the company has a solid foundation for creating durable, high-strength hardware.

Although everyone talks about the importance of quality, Ningbo Shengfa Hardware truly implements quality management in every aspect of its operations. From the inspection of incoming materials, to the monitoring of the entire production process, and finally to the evaluation of the finished product, all steps are firmly integrated into the company's quality management system. We ensure that quality is maintained throughout the entire process.

Chemical composition analysis, hardness test, tensile strength test, thread fit evaluation, corrosion resistance verification and so on are all examples of the test. Each batch is accurate, thanks to automated measurement techniques that minimize human error.

We promise our customers that every bolt, nut or forged item they receive will work exactly as intended. This commitment to quality extends beyond the company's internal operations. Customers in Southeast Asia, North America and Europe have begun to believe in this reliability.

long-standing customers are actively encouraging us to expand our overseas market, as their own businesses are also expanding globally. Of course, expanding into overseas markets presents significant challenges, such as understanding international standards, logistics, and compliance requirements, all of which we need to thoroughly address.

Our factory has always focused on manufacturing hardware components for industries such as renewable energy and construction equipment. Over the years, our products not only meet international standards like ISO, DIN, and ASTM, but also precisely match our customers' specific needs. It is this reliability that has made our components a critical part of numerous infrastructure projects and equipment worldwide, and our quality and reputation have stood the test of time.

In stark contrast to the start of small-scale operations, the factory is now confidently shipping around the world. This growth is not only an important business achievement, but also evidence of our ability to change and improve over time.

With the improvement of global environmental standards, modern hardware factories must strike a balance between sustainability and performance. Shengfa has implemented eco-friendly surface treatment technology, energy-saving technology and waste heat recovery as a greener production process.

Reducing industrial emissions and recycling materials is also our top priority. These initiatives serve international customers who must comply with stringent environmental requirements while also helping to create a more sustainable future.

Sustainability is now a necessary part of contemporary industry. In addition, our efforts ensure that it can adapt to changing industry standards.

The hardware department is developing very rapidly. Now, with the explosive growth of automation, new energy, and smart devices, the market demand for customized parts is increasing.

In order to provide professional solutions for these cutting-edge applications, we have been investing heavily in improving design capabilities, developing new tools, and researching innovative materials.

In order to remain competitive in the innovation-driven market, we directly cooperate with customers for design optimization, prototype design and material selection.

The development history of Ningbo Shengfa Hardware Factory shows a clear trajectory of improvement. Like many Chinese companies, it started from manual labor and a small local workshop, initially only producing simple tools for local customers. Shengfa has now completely transformed itself, successfully becoming a globally renowned hardware product manufacturer thanks to its reliability, high quality, and technological strength.

This trip shows our concept in addition to business progress. Dedication is the basis of strength. Discipline is the source of precision. Moreover, it will take years of commitment to gain the trust of the peoples of the world.

One forged component at a time, one shipment at a time, one happy customer, from the workshop to the global stage.